| |

| Names | |

|---|---|

| IUPAC name

2-(phenoxymethyl)oxirane | |

| Other names

Phenyl glycidyl ether; Phenylglycidyl ether; Phenol glycidyl ether; Phenol-glycidaether; Phenoxypropene oxide; Phenoxypropylene oxide; Phenyl 2,3-epoxypropyl ether; Phenylglycydyl ether; Propane, 1,2-epoxy-3-phenoxy-; Oxirane, 2-(phenoxymethyl)- | |

| Identifiers | |

3D model (JSmol) |

|

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.004.144 |

| EC Number |

|

| KEGG | |

PubChem CID |

|

| RTECS number |

|

| UNII | |

| UN number | 2810 |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C9H10O2 | |

| Molar mass | 150.177 g·mol−1 |

| Melting point | 3.5 °C (38.3 °F; 276.6 K) |

| Boiling point | 245 °C (473 °F; 518 K) |

| Hazards | |

| GHS labelling:[1] | |

| |

| Warning | |

| H315, H317, H332, H335, H341, H350, H412 | |

| P203, P261, P264, P271, P272, P273, P280, P281, P302+P352, P304+P340, P317, P318, P319, P321, P332+P317, P333+P313, P362+P364, P403+P233, P405, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

Infobox references | |

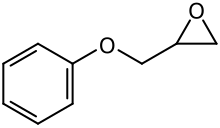

Phenyl glycidyl ether, is a liquid aromatic organic chemical in the glycidyl ether class of compounds.[2] It has the formula C9H10O2. It has the CAS Registry Number 122-60-1 and the IUPAC name of 2-(phenoxymethyl)oxirane. A key use is in the viscosity reduction of epoxy resin systems.[3][4] It is REACH registered and on EINECS under the name 2,3-epoxypropyl phenyl ether.[5]

Manufacture

Phenol and epichlorohydrin are reacted in the presence of a base and not a Lewis acid catalyst as normal with glycidyl ethers. A halohydrin is formed. This is followed by washing with sodium hydroxide in dehydrochlorination step. This forms phenyl glycidyl ether. The waste products are water and sodium chloride and excess caustic soda. One of the quality control tests would involve measuring the Epoxy value by determination of the epoxy equivalent weight.[6]

Other names

- phenyl glycidyl ether

- phenol glycidyl ether

- 1,2-Epoxy-3-phenoxypropane

- 1-Phenoxy-2,3-epoxypropane

- 2,3-Epoxy-1-phenoxypropane

- 2,3-Epoxypropyl phenyl ether

- 3-phenoxy-1,2-epoxypropane

- benzene, (2,3-epoxypropoxy)-

- Ether, 2,3-epoxypropyl phenyl

- Glycidyl phenyl ether

- Oxirane, (phenoxymethyl)-

- propane, 1,2-epoxy-3-phenoxy-

Uses

It has been used for carbon dioxide absorption[8] and other chemical reactions in addition to its use of reducing viscosity of epoxy resins.[9][10][11][12][13] It undergoes anionic polymerization.[14] It is one of a number of glycidyl ethers available commercially that are used to reduce the viscosity of epoxy resins.[15][16] These are then further used in coatings, sealants, adhesives and elastomers.[17] The use of the diluent does effect mechanical properties and microstructure of epoxy resins.[18][19]

Toxicology

It has caused cancer in laboratory animals.[20] It is also listed as a California Proposition 65 chemical.[21] It is specifically mentioned by OSHA.[22][23]

See also

References

- ↑ "Phenyl glycidyl ether". pubchem.ncbi.nlm.nih.gov. Retrieved 1 June 2022.

- ↑ Okumura, T. (1991). "retention indices of environmental chemicals on methyl silicone capillary column". Journal of Environmental Chemistry. 1 (2): 333–358. doi:10.5985/jec.1.333.

- ↑ Jagtap, Ameya Rajendra; More, Aarti (2022-08-01). "Developments in reactive diluents: a review". Polymer Bulletin. 79 (8): 5667–5708. doi:10.1007/s00289-021-03808-5. ISSN 1436-2449. S2CID 235678040.

- ↑ PubChem. "Phenyl glycidyl ether". pubchem.ncbi.nlm.nih.gov. Retrieved 2022-05-31.

- ↑ "Substance Information - ECHA". echa.europa.eu. Retrieved 2022-05-31.

- ↑ CN 104592167, Yang, Hua; Hu, Denghua & Xiao, Huaqing et al., "Method for preparing phenyl glycidyl ether", published 2015-05-06, assigned to Hubei Greenhome Fine Chemical Co. Ltd.

- ↑ "phenyl glycidyl ether | C9H10O2 | ChemSpider". www.chemspider.com. Retrieved 2022-05-31.

- ↑ Duan, Jun-Sheng; Rach, Randolph; Wazwaz, Abdul-Majid (2015-04-01). "Steady-state concentrations of carbon dioxide absorbed into phenyl glycidyl ether solutions by the Adomian decomposition method". Journal of Mathematical Chemistry. 53 (4): 1054–1067. doi:10.1007/s10910-014-0469-z. ISSN 1572-8897. S2CID 121663161.

- ↑ "Phenyl Glycidyl Ether - an overview | ScienceDirect Topics". www.sciencedirect.com. Retrieved 2022-05-31.

- ↑ Massingill, J. L.; Bauer, R. S. (2000-01-01), Craver, Clara D.; Carraher, Charles E. (eds.), "EPOXY RESINS", Applied Polymer Science: 21st Century, Oxford: Pergamon, pp. 393–424, doi:10.1016/b978-008043417-9/50023-4, ISBN 978-0-08-043417-9, retrieved 2022-05-31

- ↑ Schechter, Leon; Wynstra, John; Kurkjy, Raymond (July 1957). "Chemistry of Styrene Oxide. Comparison with Phenyl Glycidyl Ether in Model Compound Reactions". Industrial & Engineering Chemistry. 49 (7): 1107–1109. doi:10.1021/ie50571a031. ISSN 0019-7866.

- ↑ Luo, M.; Zhang, X.-H.; Darensbourg, D. J. (2015). "Highly regioselective and alternating copolymerization of carbonyl sulfide with phenyl glycidyl ether". Polymer Chemistry. 6 (39): 6955–6958. doi:10.1039/C5PY01197C. ISSN 1759-9954.

- ↑ Saranya, K.; Mohan, V.; Rajendran, L. (2020-06-01). "Steady-state concentrations of carbon dioxide absorbed into phenyl glycidyl ether solutions by residual method". Journal of Mathematical Chemistry. 58 (6): 1230–1246. doi:10.1007/s10910-020-01127-0. ISSN 1572-8897. S2CID 215820069.

- ↑ Maitre, Catherine; Ganachaud, François; Ferreira, Odette; Lutz, Jean François; Paintoux, Yannick; Hémery, Patrick (September 2000). "Anionic Polymerization of Phenyl Glycidyl Ether in Miniemulsion". Macromolecules. 33 (21): 7730–7736. Bibcode:2000MaMol..33.7730M. doi:10.1021/ma0007132 – via American Chemical Society.

- ↑ Monte, Salvatore J. (1998), Pritchard, Geoffrey (ed.), "Diluents and viscosity modifiers for epoxy resins", Plastics Additives: An A-Z reference, Polymer Science and Technology Series, Dordrecht: Springer Netherlands, vol. 1, pp. 211–216, doi:10.1007/978-94-011-5862-6_24, ISBN 978-94-011-5862-6, retrieved 2022-03-29

- ↑ US 6987144, Anderson, Lawrence G.; De Saw, Shawn A. & Hartman, Marvis E. et al., "Flexible coating compositions having improved scratch resistance, coated substrates and methods related thereto", published 2006-01-17, assigned to PPG Industries, Ohio Inc.

- ↑ Howarth G.A "Synthesis of a legislation compliant corrosion protection coating system based on urethane, oxazolidine and waterborne epoxy technology" pages 23,24,39 Master of Science Thesis April 1997 Imperial College London

- ↑ Khalina, Morteza; Beheshty, Mohammad Hosain; Salimi, Ali (2019-08-01). "The effect of reactive diluent on mechanical properties and microstructure of epoxy resins". Polymer Bulletin. 76 (8): 3905–3927. doi:10.1007/s00289-018-2577-6. ISSN 1436-2449. S2CID 105389177.

- ↑ Pastarnokienė, Liepa; Jonikaitė-Švėgždienė, Jūratė; Lapinskaitė, Neringa; Kulbokaitė, Rūta; Bočkuvienė, Alma; Kochanė, Tatjana; Makuška, Ričardas (2023-07-01). "The effect of reactive diluents on curing of epoxy resins and properties of the cured epoxy coatings". Journal of Coatings Technology and Research. 20 (4): 1207–1221. doi:10.1007/s11998-022-00737-4. ISSN 1935-3804. S2CID 256749849.

- ↑ "CDC - NIOSH Pocket Guide to Chemical Hazards - Phenyl glycidyl ether". www.cdc.gov. Retrieved 2022-05-31.

- ↑ "Phenyl glycidyl ether listing". oehha.ca.gov. Retrieved 2022-05-31.

- ↑ "PHENYL GLYCIDYL ETHER (PGE) | Occupational Safety and Health Administration". www.osha.gov. Retrieved 2022-05-31.

- ↑ "phenyl glycidyl ether | Allergic Contact Dermatitis Database". www.contactdermatitisinstitute.com. Retrieved 2022-05-31.

Further reading

- Epoxy resin technology. Paul F. Bruins, Polytechnic Institute of Brooklyn. New York: Interscience Publishers. 1968. ISBN 0-470-11390-1. OCLC 182890.

{{cite book}}: CS1 maint: others (link) - Flick, Ernest W. (1993). Epoxy resins, curing agents, compounds, and modifiers : an industrial guide. Park Ridge, NJ. ISBN 978-0-8155-1708-5. OCLC 915134542.

{{cite book}}: CS1 maint: location missing publisher (link) - Lee, Henry (1967). Handbook of epoxy resins. Kris Neville ([2nd, expanded work] ed.). New York: McGraw-Hill. ISBN 0-07-036997-6. OCLC 311631322.

- "Dow Epoxy Resins" (PDF).